- 【山东省教育厅】欧宝登录app入口官网:“五大工程”推进全环境立德...2023-03-03

- 【参考消息】欧宝登录app入口官网:创新书院制改革 构建“一站式”学...2022-09-04

- 【中国城市报】欧宝登录app入口官网:全员书院制培育高情商经营管理人才2022-09-01

- 【中国教育报】欧宝登录app入口官网 特色鲜明以生为本 狠抓质量擘画...2022-05-18

- 【最泰安】泰安小美在身边丨引导、答疑忙不停,志愿者“集小...2023-04-30

- 【泰山晚报】欧宝登录app入口官网师生共创“师生派对”2023-04-17

- 【我和泰科的故事】任一鑫:愿做一位“有责任有爱心有良心”...2023-03-01

- 就业典型 | 敢于拼搏的青春,才能收获成功—尹树喆2022-11-25

- “泰山百万自强扶助基金”获得者——陈宇航:学习改变命运2022-09-28

- “泰山百万自强扶助基金”获得者——葛睿杰:把能决定的5%做好2022-09-28

- “泰山百万自强扶助基金”获得者——刘燕:起于低谷,也要逆...2022-09-28

- 我所怀念的母校2022-09-26

- 292023-04“虚拟教研室”“扎实”推进会——会计学虚拟教研室三校四区第一次全体会议

- 292023-04淬炼商学院开展“教学优秀奖”获奖教师示范课

- 292023-04数字化赋能组织人才发展——中国人力资源科技年度峰会参会分享

- 292023-04群策群力 统筹计划 精准安排——淬炼商学院课程进度论证会

- 292023-04智能工程学院青年教师成长导师胡新颜教授系列讲座之七——如何指导学科竞赛

- 282023-04通识教学部召开年度重点工作阶段汇报总结会

- 292023-04【辅导员沙龙第20期】思享•提升

- 282023-04大数据学院五一节前宿舍安全检查工作顺利开展

- 282023-04大数据学院第4期“院长共膳日”顺利开展

- 262023-04【艺术传媒学院】学风建设第3期:“学之染人,甚于丹青”活动

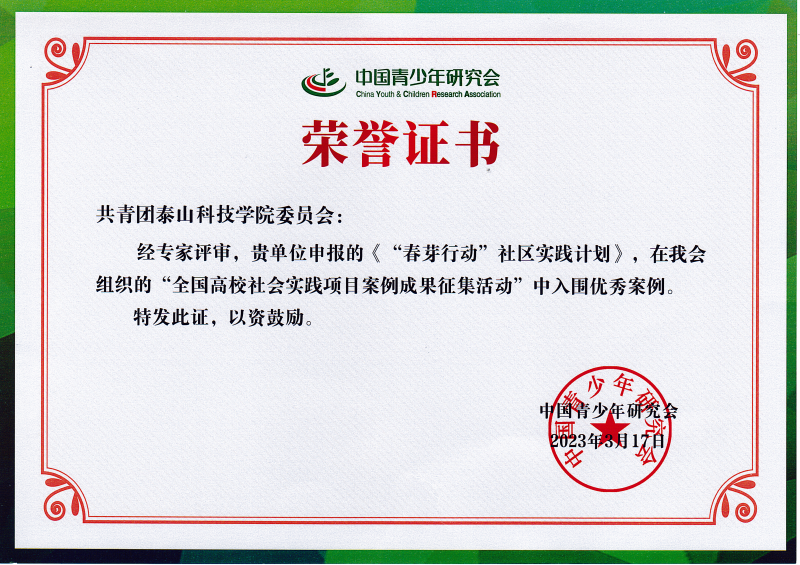

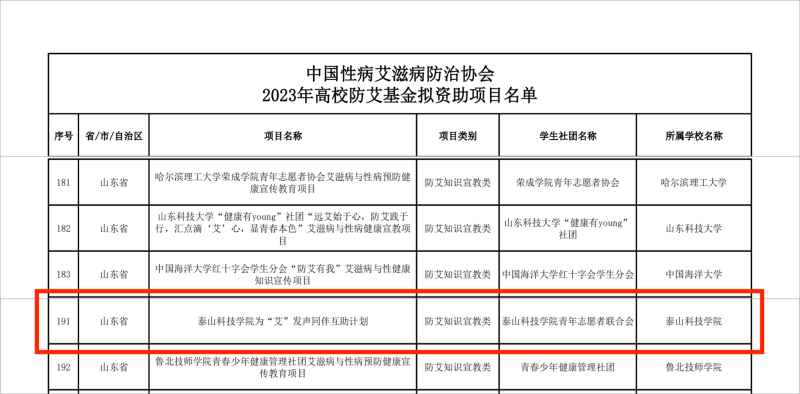

- 242023-04砥砺深耕,铺设发展型资助新道路

- 222023-04【 艺术传媒学院】学风督察第九期

- 302023-042023年退役大学生士兵专升本综合考查流程须知

- 292023-04欧宝登录app入口官网泰山“青未了杯”大学生电子竞技大赛总决赛舞台搭建招标公告

- 252023-04欧宝登录app入口官网大学生活动剧场LED屏幕建设招标公告

- 252023-04欧宝登录app入口官网大学生活动剧场沉浸式投影设备建设招标公告

- 242023-04英国伯明翰大学学院合作项目招生

- 182023-04欧宝登录app入口官网在线课程制作及运行服务招标公告